Ukubheka amamotho ahlukene alayini atholakalayo nokuthi ungakhetha kanjani uhlobo olufanele lohlelo lwakho lokusebenza.

Isihloko esilandelayo siwukubukezwa kwezinhlobo ezahlukene zamamotho alayini atholakalayo, okuhlanganisa nemigomo yokusebenza kwawo, umlando wokuthuthukiswa kozibuthe baphakade, izindlela zokuklama zamamotho alayini kanye nezimboni zezimboni zisebenzisa uhlobo ngalunye lwenjini yomugqa.

I-Linear Motor Technology ingaba: I-Linear Induction Motors (LIM) noma I-Permanent Magnet Linear Synchronous Motors (PMLSM).I-PMLSM ingaba yinsimbi noma ingabi nensimbi.Wonke ama-motor atholakala ngokucushwa okuyisicaba noma kwe-tubular.U-Hiwin ubeseqhulwini ekwakhiweni kwezimoto ezilayini kanye nokukhiqiza iminyaka engama-20.

Izinzuzo Linear Motors

Injini yomugqa isetshenziselwa ukuhlinzeka ngokunyakaza okuqondile, okungukuthi, ukuhambisa umthwalo okhokhelwayo owunikeziwe ngesivinini esinqunyiwe, isivinini, ibanga lokuhamba kanye nokunemba.Bonke ubuchwepheshe bokunyakaza ngaphandle kwe-linear motor driven luhlobo oluthile lokushayela kwemishini ukuguqula ukunyakaza okujikelezayo kube ukunyakaza okuqondile.Amasistimu okunyakaza anjalo aqhutshwa yizikulufu zebhola, amabhande noma i-rack ne-pinion.Impilo yesevisi yawo wonke lawa madrayivu incike kakhulu ekugugelweni kwezinto ezisetshenziswayo ukuguqula ukunyakaza okujikelezayo kube ukunyakaza okulandelanayo futhi imfushane kakhulu.

Inzuzo enkulu yamamotho alayini ukuhlinzeka ngokunyakaza ngomugqa ngaphandle kwanoma yiluphi uhlelo lomshini ngoba umoya uyindawo yokudlulisela, ngakho-ke amamotho alayini empeleni angamadrayivu angenawo ukungqubuzana, anikeza impilo yesevisi engenamkhawulo.Ngenxa yokuthi azikho izingxenye zemishini ezisetshenziselwa ukukhiqiza ukunyakaza okuqondile, ukusheshisa okuphezulu kakhulu isivinini singenzeka lapho ezinye izishayeli ezinjengezikulufu zebhola, amabhande noma i-rack kanye nephinikhodi zizohlangabezana nemikhawulo engathi sína.

I-Linear Induction Motors

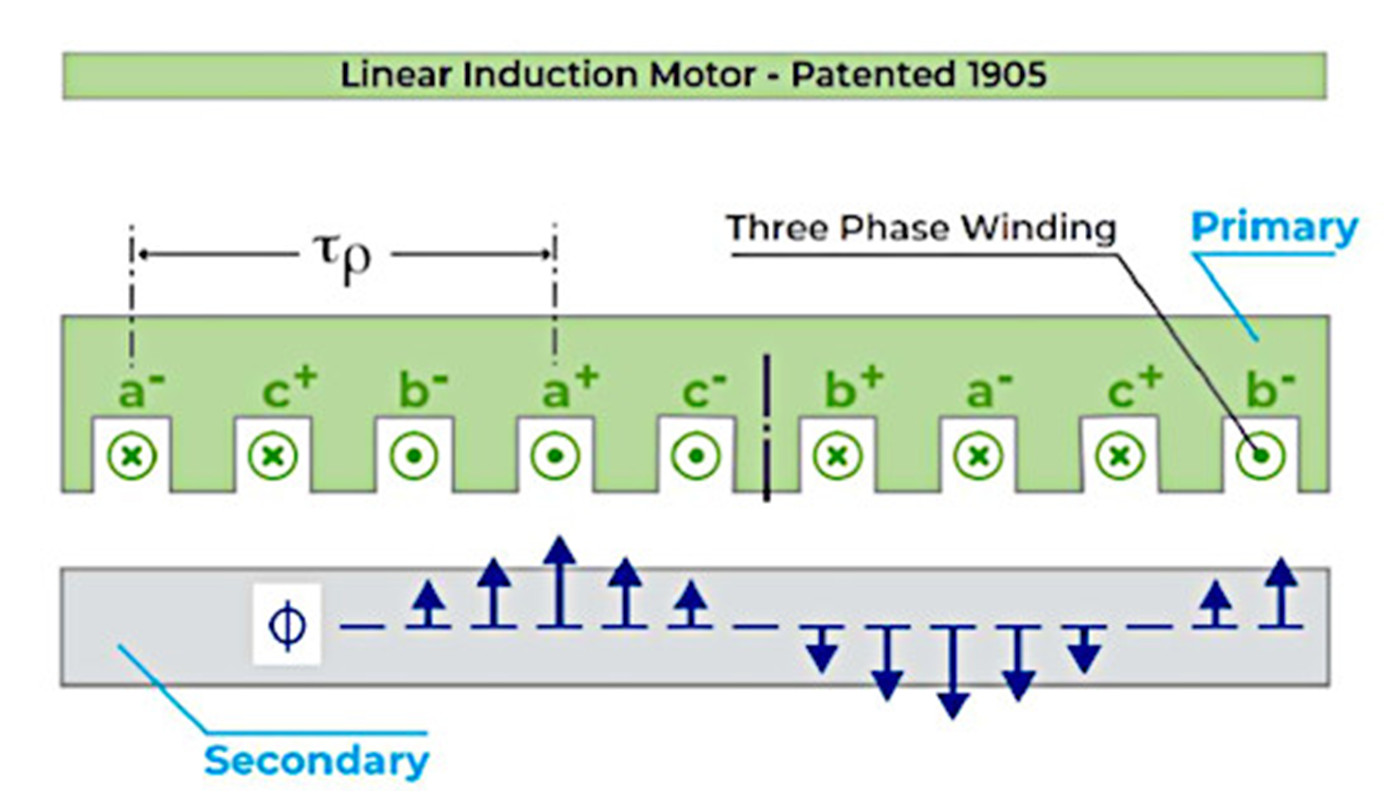

Umdwebo 1

I-linear induction motor (LIM) yasungulwa okokuqala (i-US patent 782312 - Alfred Zehden ngo-1905).Iqukethe "okuyisisekelo" esakhiwe isitaki sezinsimbi zikagesi kanye nobuningi bamakhoyili ethusi anikezwa amandla kagesi wezigaba ezintathu kanye "nesesibili" ngokuvamile esakhiwa ipuleti lensimbi kanye nepuleti lethusi noma le-aluminium.

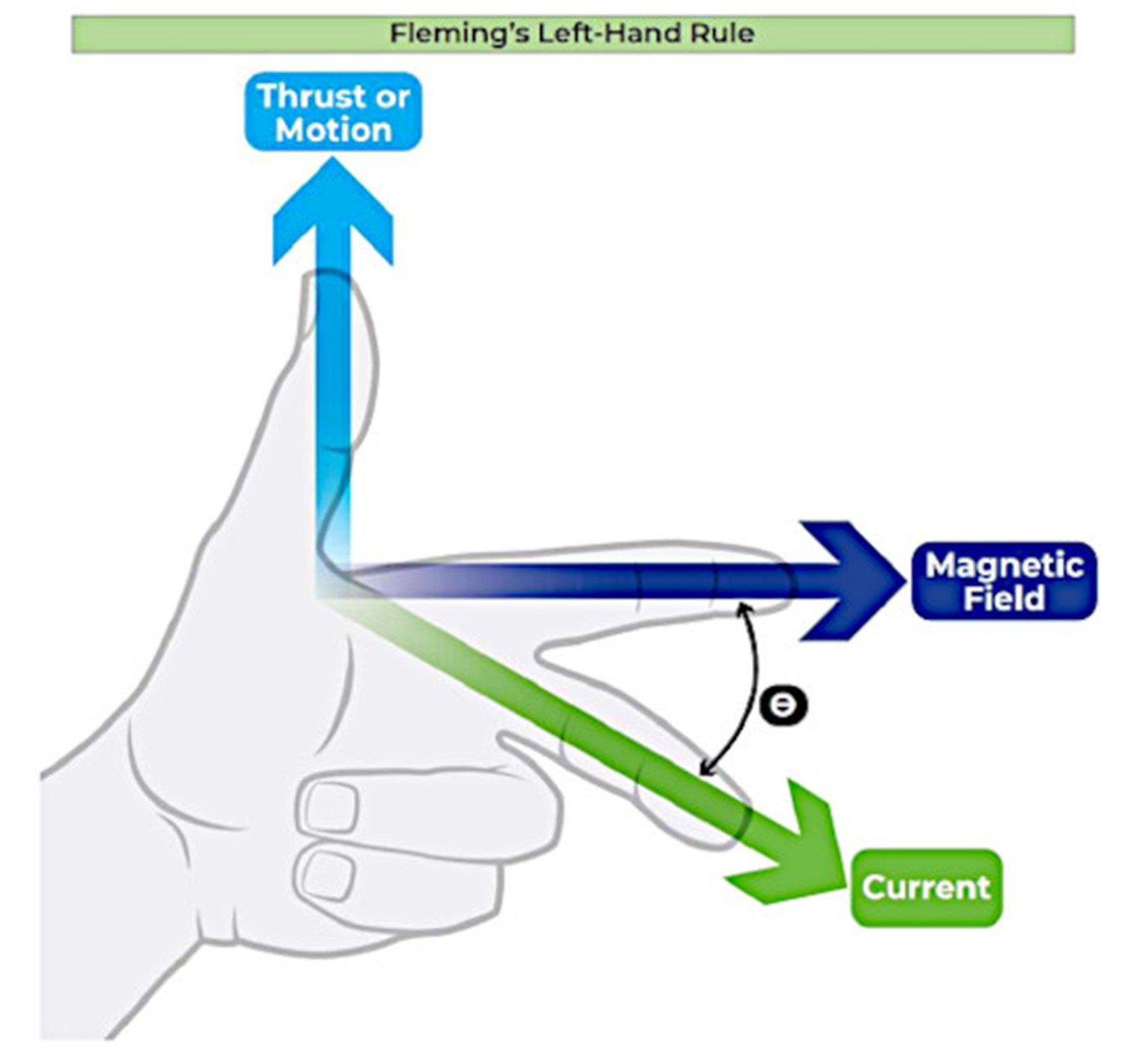

Uma amakhoyili okuqala enikwa amandla okwesibili kuba nguzibuthe bese kwakheka insimu yama-eddy currents ku-conductor yesibili.Le nkambu yesibili izobe isisebenzisana ne-EMF engemuva ukuze ikhiqize amandla.Indlela yokunyakaza izolandela umthetho kaFleming ongakwesokunxele okungukuthi;isiqondiso sokunyakaza sizoba se-perpendicular to direction of current and direction of field / flux.

Umdwebo 2

Ama-Linear induction motors anikeza inzuzo yezindleko eziphansi kakhulu ngoba eyesibili ayisebenzisi noma yimaphi amamagnethi ahlala njalo.Ozibuthe be-NdFeB kanye ne-SmCo babiza kakhulu.Ama-motor induction motors asebenzisa izinto ezivame kakhulu, (insimbi, i-aluminium, ithusi), okwesibili futhi asuse le ngozi yokuhlinzekwa.

Kodwa-ke, uhlangothi olubi lokusebenzisa ama-motor induction linear ukutholakala kwamadrayivu anjalo.Yize kulula kakhulu ukuthola amadrayivu amamotho alayini azibuthe ahlala unomphela, kunzima kakhulu ukuthola amadrayivu amamotho wokungenisa aqondile.

Umdwebo 3

I-Permanent Magnet Linear Synchronous Motors

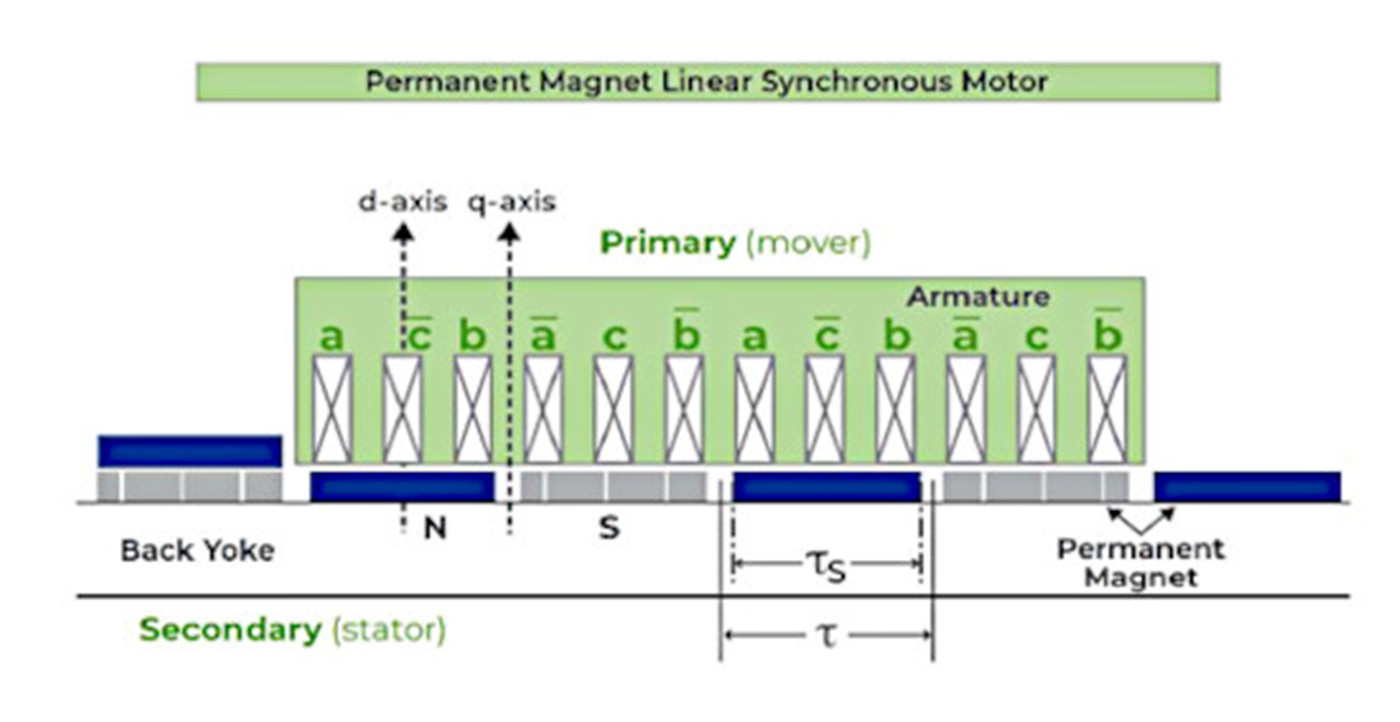

Amamotho kazibuthe alayini we-synchronous motors (PMLSM) anesisekelo esifanayo namamotho angenisayo alayini (okungukuthi, isethi yamakhoyili abekwe esitakini samalayimu ensimbi kagesi futhi ashayelwa amandla kagesi ezigaba ezintathu).Okwesibili kuyehluka.

Esikhundleni sepuleti le-aluminium noma lethusi elifakwe epuleti lensimbi, elesibili lakhiwe ngozibuthe abangapheli abafakwe epuleti lensimbi.Isiqondiso sikazibuthe ngasinye sokuzibuthe sizoshintshana ngokuphathelene nangaphambili njengoba kuboniswe ku-Fig. 3.

Inzuzo esobala yokusebenzisa odonsa unomphela ukudala insimu engapheli endaweni yesibili.Sibonile ukuthi amandla akhiqizwa injini yokungeniswa ngokusebenzisana kwenkundla yokuqala kanye nenkundla yesibili etholakala kuphela ngemva kokuba insimu yama-eddy currents idalwe kwesibili nge-motor airgap.Lokhu kuzoholela ekubambezelekeni okubizwa ngokuthi "ukushelela" kanye nokunyakaza kwesibili okungavumelani ne-voltage eyinhloko enikezwa kwesisekelo.

Ngenxa yalesi sizathu, ama-motor linear induction abizwa ngokuthi "asynchronous".Emotweni eqondile kazibuthe unomphela, ukunyakaza kwesibili kuzohlala kuhambisana ne-voltage eyinhloko ngoba inkambu yesibili ihlala ikhona futhi ngaphandle kokubambezeleka.Ngenxa yalesi sizathu, amamotho emigqa ehlala njalo abizwa ngokuthi "synchronous".

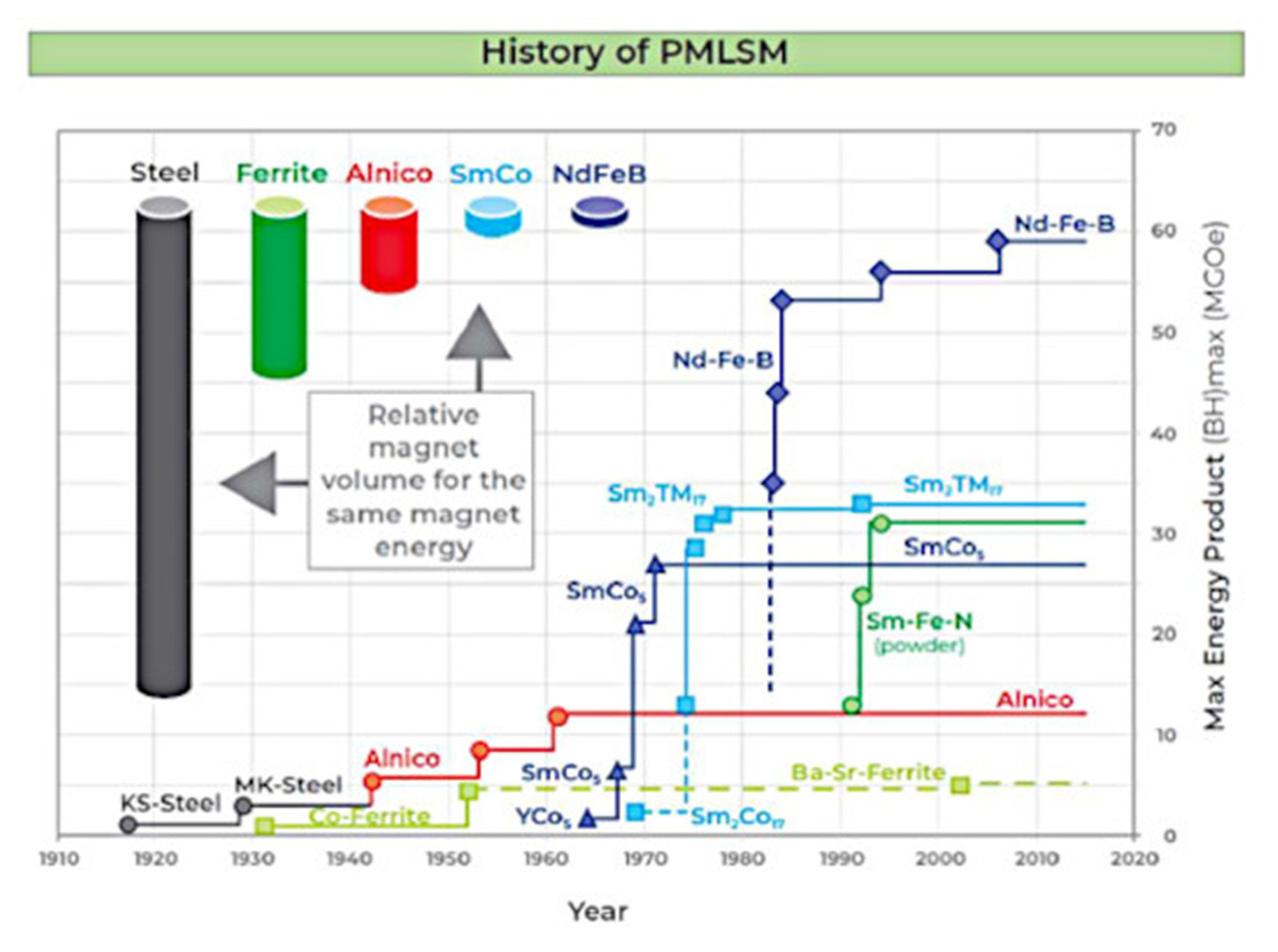

Izinhlobo ezahlukene zozibuthe ezihlala njalo zingasetshenziswa ku-PMLSM.Kule minyaka engu-120 edlule, isilinganiso sento ngayinye sishintshile.Kusukela namuhla, ama-PMLSM asebenzisa omazibuthe be-NdFeB noma omagnethi be-SmCo kodwa iningi labo lisebenzisa omagnet be-NdFeB.Umfanekiso wesi-4 ubonisa umlando wokuthuthukiswa kukazibuthe Okuphakade.

Umdwebo 4

Amandla kazibuthe abonakala ngomkhiqizo wawo wamandla e-Megagauss-Oersteds, (MGOe).Kuze kube maphakathi nawo-eighties kuphela i-Steel, i-Ferrite ne-Alnico eyayitholakala futhi iletha imikhiqizo yamandla aphansi kakhulu.Ozibuthe be-SmCo bathuthukiswa ekuqaleni kwawo-1960 ngokusekelwe emsebenzini ka-Karl Strnat kanye no-Alden Ray futhi kamuva bathengiswa ngasekupheleni kweminyaka engamashumi ayisithupha.

Umdwebo 5

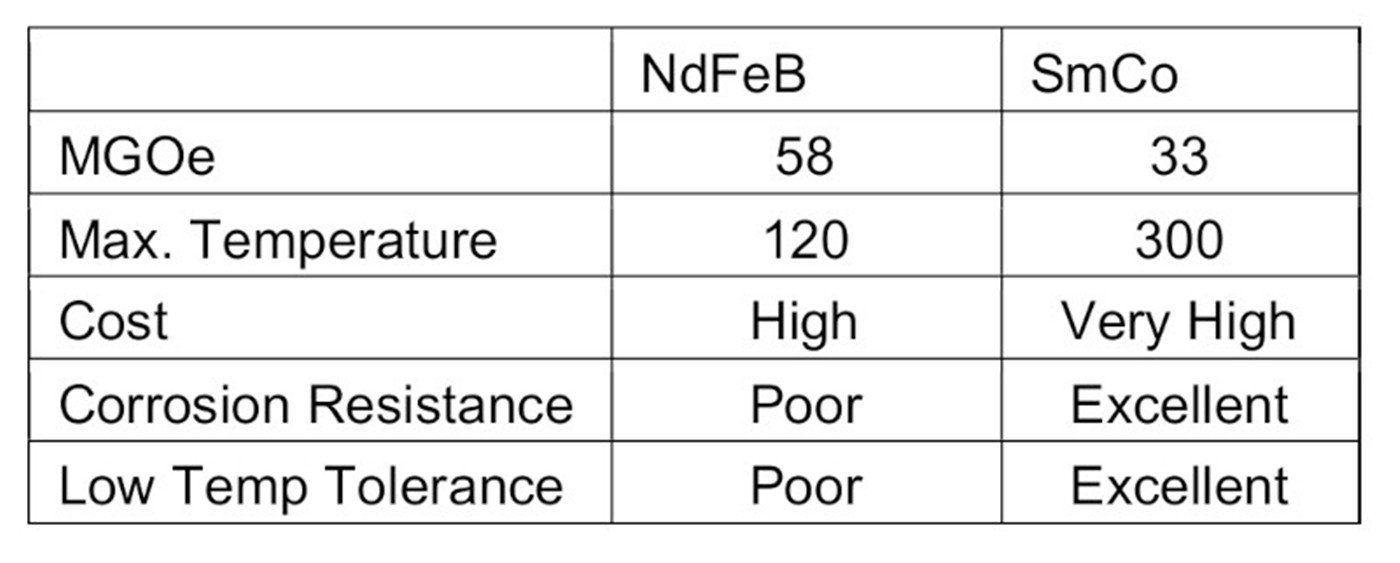

Umkhiqizo wamandla kamagnethi we-SmCo ekuqaleni wawungaphezu kokuphindwe kabili komkhiqizo wamandla wozibuthe be-Alnico.Ngo-1984 iGeneral Motors neSumitomo bazenzela ngokuzimela omazibuthe be-NdFeB, inhlanganisela ye-Neodynium, Iron ne-Boron.Ukuqhathaniswa kozibuthe be-SmCo kanye ne-NdFeB kuboniswa ku-Fig. 5.

Ozibuthe be-NdFeB bathuthukisa amandla aphezulu kakhulu kunozibuthe be-SmCo kodwa bazwela kakhulu emazingeni okushisa aphezulu.Ozibuthe be-SmCo nabo bamelana kakhulu nokugqwala namazinga okushisa aphansi kodwa babiza kakhulu.Lapho izinga lokushisa lokusebenza lifinyelela izinga lokushisa eliphakeme likakazibuthe uzibuthe uqala ukuwohloka, futhi lokhu kususwa kazibuthe akubuyiseleki emuva.Umazibuthe olahlekelwa yizibuthe kuzobangela ukuthi injini ilahlekelwe amandla futhi ingakwazi ukuhlangabezana nemininingwane.Uma uzibuthe usebenza ngaphansi kwezinga lokushisa elingaphansi kuka-100% wesikhathi, amandla awo azogcinwa cishe unomphela.

Ngenxa yezindleko eziphakeme zozibuthe be-SmCo, omagnet be-NdFeB bayisinqumo esifanele kumamotho amaningi, ikakhulukazi uma kubhekwa amandla aphezulu atholakalayo.Nokho, kwezinye izinhlelo zokusebenza lapho izinga lokushisa lokusebenza liphezulu kakhulu kungcono ukusebenzisa omagnethi be-SmCo ukuze uhlale kude nezinga lokushisa eliphezulu lokusebenza.

Idizayini yama-Linear motors

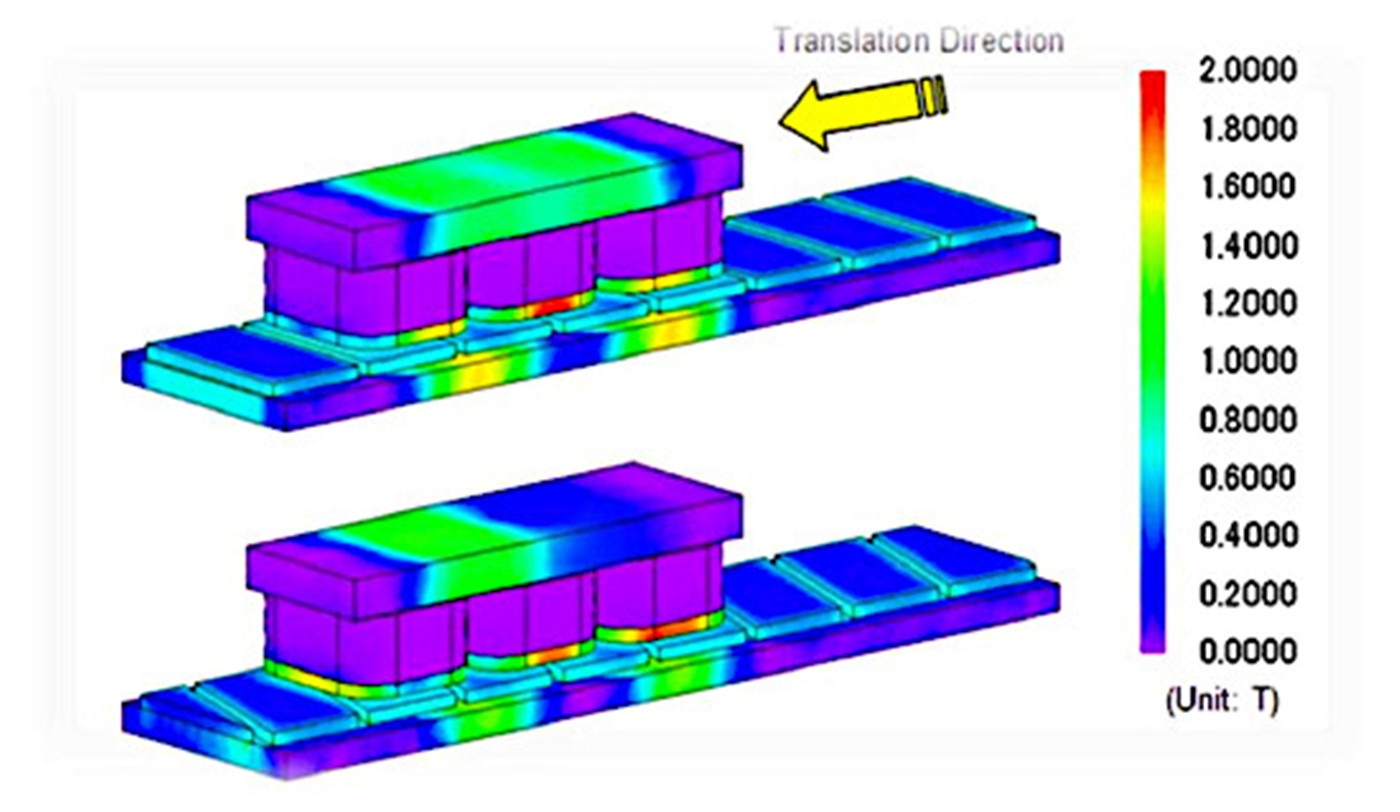

I-linear motor ngokuvamile iklanywa nge-Finite Element Electromagnetic Simulation.Imodeli ye-3D izokwakhiwa ukumela isitaki se-lamination, amakhoyili, omazibuthe, ne-steel plate esekela omazibuthe.Umoya uzomodela eduze kwenjini kanye nase-airgap.Khona-ke izakhiwo zezinto ezibonakalayo zizofakwa kuzo zonke izingxenye: omazibuthe, insimbi kagesi, insimbi, amakhoyili, nomoya.I-mesh izobe isidalwa kusetshenziswa izakhi ze-H noma ze-P futhi imodeli izoxazululwa.Khona-ke i-current isetshenziswa kukhoyili ngayinye kumodeli.

Umdwebo 6 ubonisa okukhiphayo kokulingisa lapho ukugeleza kwe-tesla kuboniswa khona.Inani elikhulu lokukhiphayo lenzalo yokulingiswa yiqiniso ukuthi i-Motor Force futhi izotholakala.Ngenxa yokuthi iziphetho zamakhoyili azikhiqizi noma yimaphi amandla, kungenzeka futhi ukusebenzisa ukulingisa kwe-2D ngokusebenzisa imodeli engu-2D (i-DXF noma enye ifomethi) yenjini okuhlanganisa ama-laminations, omagnethi, nepuleti lensimbi elisekela omazibuthe.Okukhishwayo kwalokhu sekulingisa kwe-2D kuzosondela kakhulu ekulingiseni kwe-3D futhi kunembe ngokwanele ukuze kuhlolwe amandla emoto.

Umdwebo 6

I-linear induction motor izomodelwa ngendlela efanayo, kungaba ngemodeli ye-3D noma ye-2D kodwa ukuxazulula kuzoba nzima kakhulu kune-PMLSM.Lokhu kungenxa yokuthi i-flux kazibuthe yesibili ye-PMLSM izomodelwa khona manjalo ngemva kokufaka izakhiwo zikazibuthe, ngakho-ke kuyodingeka isisombululo esisodwa ukuze kutholwe wonke amanani okukhiphayo okuhlanganisa namandla emoto.

Kodwa-ke, i-flux yesibili ye-induction motor izodinga ukuhlaziywa kwesikhashana (okusho izixazululo eziningana ngesikhathi esithile) ukuze i-flux magnetic ye-LIM yesibili ingakhiwa bese kuphela lapho amandla angatholakala.Isofthiwe esetshenziselwa i-Electromagnetic Finite Element Simulation izodinga ukuba nekhono lokuqalisa ukuhlaziya okudlulayo.

I-Linear Motor Stage

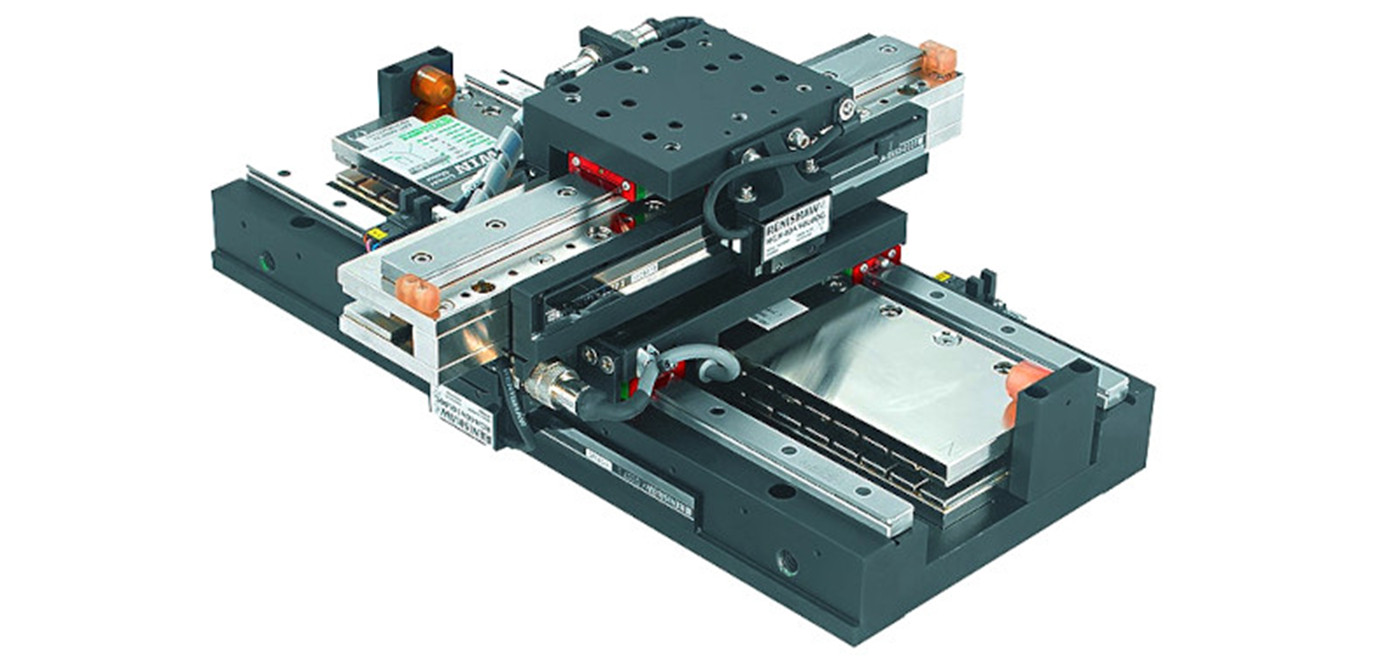

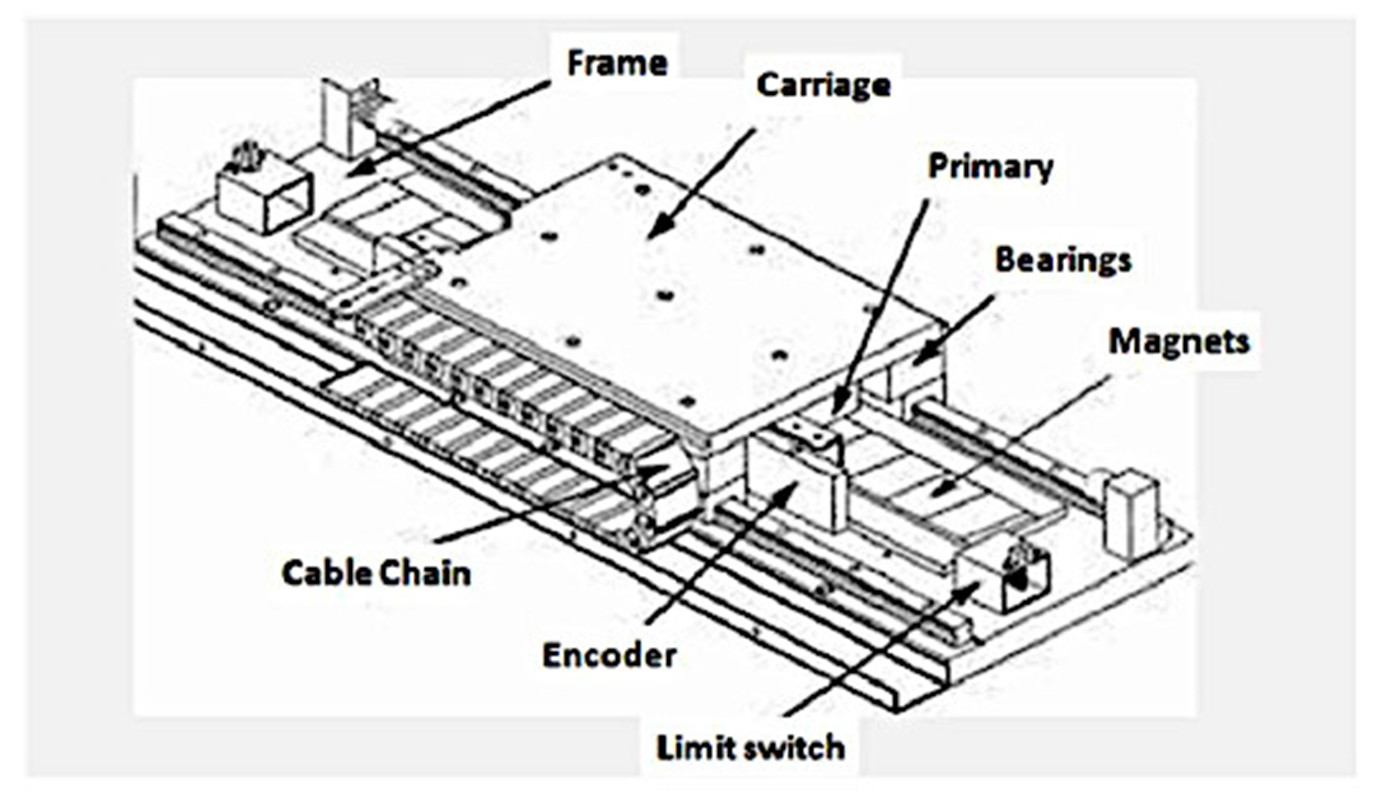

Umdwebo 7

I-Hiwin Corporation ihlinzeka ngamamotho aqondile ezingeni lengxenye.Kulesi simo, kuzolethwa injini yomugqa kuphela namamojula wesibili.Ngenjini ye-PMLSM, amamojula esibili azoqukatha amapuleti ensimbi anobude obuhlukene phezu kwawo okuzohlanganiswa omazibuthe baphakade.I-Hiwin Corporation iphinde inikeze izigaba eziphelele njengoba kuboniswe ku-Fig. 7.

Isiteji esinjalo sihlanganisa ifremu, ama-linear bearings, motor primary, omagnetic besibili, inqola ukuze ikhasimende linamathisele umthwalo walo okhokhelwayo, isishumeki sekhodi, nethrekhi yekhebula.Isiteji sezimoto esiqondile sizobe sesilungele ukuqala lapho sidiliva futhi senze ukuphila kube lula ngoba ikhasimende ngeke lidinge ukuklama nokwenza isiteji, okudinga ulwazi lochwepheshe.

I-Linear Motor Stage Service Life

Impilo yesevisi yesiteji semoto ewumugqa yinde kakhulu kunesiteji esishayelwa ibhande, isikulufu sebhola noma i-rack ne-pinion.Izingxenye zomshini zezigaba ezishayelwa ngokungaqondile ngokuvamile ziyizingxenye zokuqala ezingaphumeleli ngenxa yokungqubuzana nokuguga ezivezwa kukho ngokuqhubekayo.Isiteji semoto esiqondile siyidrayivu eqondile engenakho ukuthintana komshini noma ukugqokwa ngoba indawo yokudlulisela ingumoya.Ngakho-ke, izingxenye kuphela ezingahluleka esiteji se-motor eqondile yizinsimbi eziqondile noma injini ngokwayo.

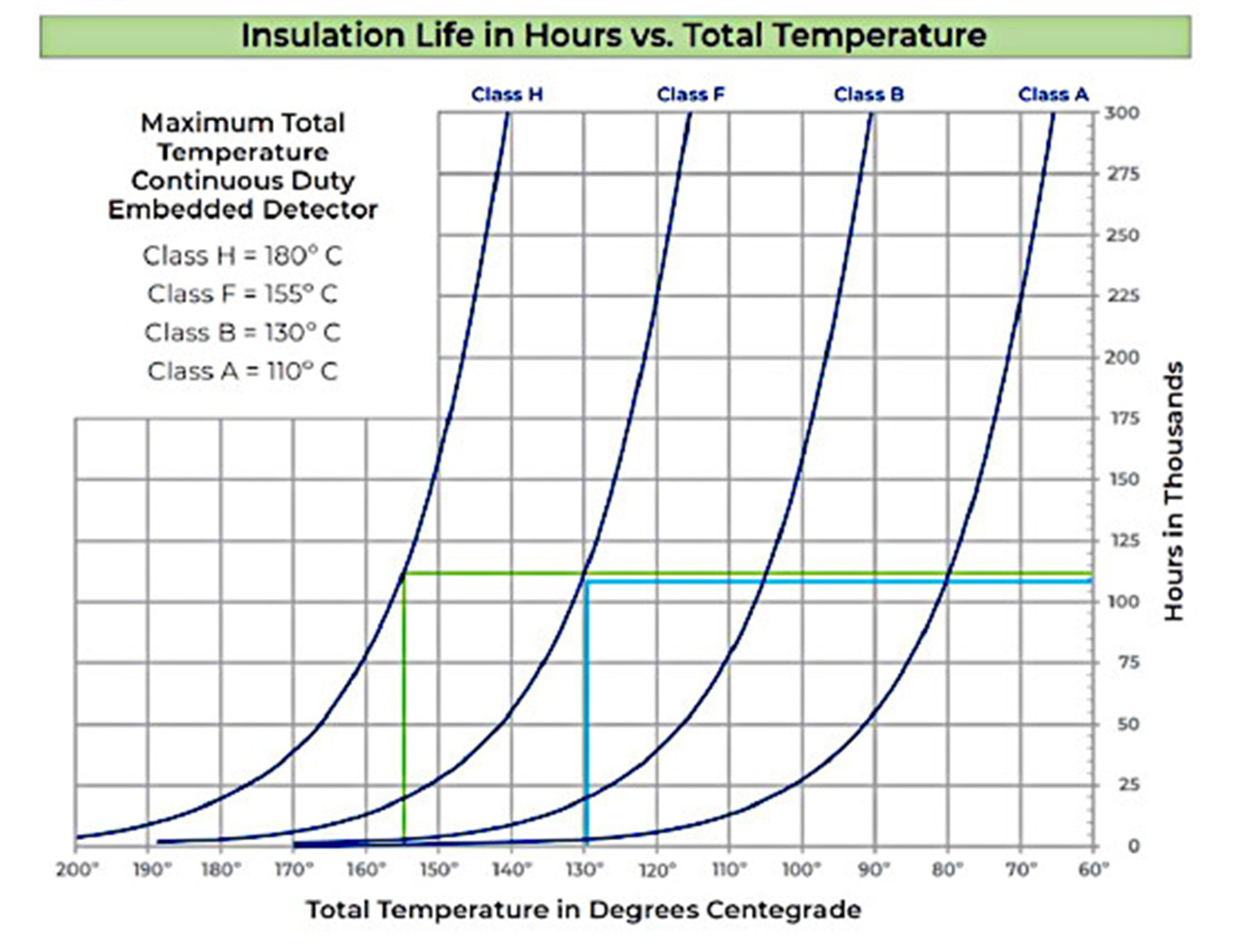

Amabheringi alayini ngokuvamile anempilo ende yesevisi ngoba umthwalo weradial uphansi kakhulu.Impilo yesevisi yemoto izoncika ekushiseni okujwayelekile okusebenzayo.Umfanekiso 8 ukhombisa impilo yokufakwa kwezimoto njengomsebenzi wokushisa.Umthetho uthi impilo yesevisi izokwehliswa ngohhafu njalo ngo-10 degrees Celsius izinga lokushisa eligijimayo libe ngaphezu kwezinga lokushisa elilinganiselwe.Isibonelo, isigaba F se-motor Insulation sizosebenza amahora angu-325,000 ngesilinganiso sokushisa esingu-120°C.

Ngakho-ke, kubonakala kusengaphambili ukuthi isiteji sezimoto esiwumugqa sizoba nempilo yesevisi yeminyaka engu-50+ uma injini ikhethwa ngendlela elondolozayo, impilo yesevisi engeke izuzwe ngebhande, isikulufu sebhola, noma izigaba ezishayelwa ngama-rack ne-pinion.

Umfanekiso 8

Izicelo ze-Linear Motors

Ama-Linear induction motors (LIM) asetshenziswa kakhulu ezinhlelweni ezinobude bohambo olude nalapho kudingeka khona amandla aphezulu kuhlanganiswe nesivinini esikhulu kakhulu.Isizathu sokukhetha i-linear induction motor kungenxa yokuthi izindleko zesibili zizoba phansi kakhulu uma usebenzisa i-PMLSM futhi ngesivinini esikhulu ukusebenza kahle kwe-Linear Induction motor kuphezulu kakhulu, ngakho-ke amandla amancane azolahleka.

Isibonelo, i-EMALS (i-Electromagnetic Launch Systems), esetshenziswa eziphathini zezindiza ukwethula izindiza zisebenzisa izinjini zokungeniswa komugqa.Uhlelo lokuqala olunjalo lwezithuthuthu lwafakwa kusithwali sezindiza i-USS Gerald R. Ford.Injini ikwazi ukusheshisa indiza engu-45,000 kg ngesivinini esingama-240 km/h kumzila wamamitha angu-91.

Esinye isibonelo sokugibela ipaki yokuzijabulisa.Amamotho afakwa kulayini afakwe kwezinye zalezi zinhlelo angasheshisa ukulayisha okuphezulu kakhulu ukusuka ku-0 kuye ku-100 km/h ngemizuzwana emi-3.Izigaba zezimoto zokungeniswa zingasetshenziswa kuma-RTU, (Amayunithi Ezokuthutha eRobhothi).Ama-RTU amaningi asebenzisa ama-rack kanye nama-pinion drives kodwa i-linear induction motor inganikeza ukusebenza okuphezulu, izindleko eziphansi, nempilo yesevisi ende kakhulu.

Permanent Magnet Synchronous Motors

Ama-PMLSMs azosetshenziswa ngokujwayelekile ezinhlelweni ezinemivimbo emincane kakhulu, isivinini esiphansi kodwa esiphezulu ukuya phezulu kakhulu kanye nemijikelezo yomsebenzi onzima.Iningi lalezi zinhlelo zokusebenza zitholakala ku-AOI (Automated Optical Inspection), i-semiconductor kanye nezimboni zemishini ye-laser.

Ukukhethwa kwezigaba ezishayelwa yimoto ewumugqa, (idrayivu eqondile), kunikeza izinzuzo zokusebenza ezibalulekile ngaphezu kokushayela okungaqondile, (izigaba lapho ukunyakaza okuqondile kutholwa ngokuguqula ukunyakaza okujikelezayo), kumadizayini ahlala isikhathi eside futhi afanele izimboni eziningi.

Isikhathi sokuthumela: Feb-06-2023